A range of shorter case studies to demonstrate range of skills, capabilities and sector experience, with both smaller businesses + some of Scotland’s largest industrial sites.

Summary Cases Showcasing – Resource Efficiency, Carbon Accounting, Opportunity Assessment + Climate Action

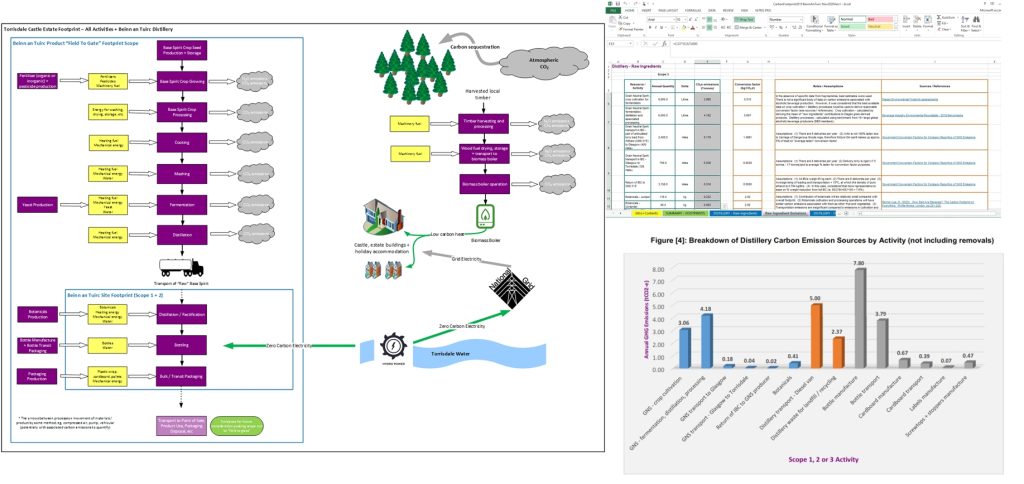

Distillers – various | West Coast + Speyside | 2020-21

During Covid-19 lockdowns, a number of distillers took the opportunity to engage Ecolibrium for desk-based carbon accounting (footprinting) – large distillers, those in planning and smaller niche (eg. Nc’nean [craft organic whisky], Beinn an Tuirc [craft gin]). Full “field-to-glass” lifecycle Scope 1, 2 + 3 carbon emissions baseline quantifications.

Facilitated insights into quantification of opportunities (in terms of carbon and cost reduction), evidence-based decision making on priorities, potential science-based targets, action to deliver, and potential Net-Zero pathways.

Also, considered implications of using different standards ongoing (GHG Protocol, ISO 14064, PAS 2050) in identifying “hotspots” of emissions and enabling demonstration of emissions reductions to customers + other stakeholders.

Diageo – Global Supply | Leven | 2003

The Ecolibrium team undertook a successful anaerobic digestion (AD) technology evaluation at Diageo’s global supply site. The on-site management team clearly thought that this was the solution to increasing volume and organic loading of various liquid waste and effluent streams. The scope covered all on-site processes, including blending and bottling operations. The project required a range of skills from quality sampling, metering and process auditing expertise, to resource efficiency + treatment option evaluation.

Ecolibrium’s resource efficiency / best practice approach, considering prevention and reduction at source, quantified significant savings in water consumption and effluent generation. However, the greatest short term benefit was the avoidance of the costs of an AD plant (once volume / organic loadings minimised via “upstream” process efficiencies recommended). This was a very positive result beyond client expectations, and also led to the embedding of a “measure to manage” resource efficiency approach to operations. Metering and monitoring became the order of the day rather than turning to high cost / risk “end-of-pipe” engineering solutions.

Heineken Caledonian Brewery | Edinburgh | 2010

The best practice approach pursued by Ecolibrium covered all stages of the brewing process from mashing to kegging. This required integrated consideration of energy, water, steam, product and effluent streams. Quantification of opportunities (in terms of carbon and cost reduction) led to prioritisation, evidence-based decision making on priorities, objectives + targets and action. Resulted in identification of more than £500 000 in cost-effective water and energy savings.

Following business case development for specific measures (eg. process bottlenecks, reduction of losses, heat recovery), monitoring systems were also upgraded to allow better evidence-based decision-making, ongoing continual improvement and reporting of resource, waste and carbon data to group sustainability team.

Envirowise UK Government best practice initiative | 2001 – 2011

Selected 3 times for this business Resource Efficiency (RE) best practice panel / initiative. Contributed to DEFRA / DTI best practice guidance. Undertook >150 on-site RE audits across wide range of manufacturing and process industry sectors.

Objectives to identify and quantify resource, cost and carbon saving opportunities, in order to demonstrate short payback on carbon emissions reduction options and benefits of systematic process. Quantification of opportunities (in terms of carbon and cost reduction), prioritisation, evidence-based decision making on priorities, objectives + targets and action to deliver.

Derek Panton, Ecolibrium Sustainable Business Specialist, was Scotland’s most used specialist in this initiative. Indeed, in subsequent govt. resource efficiency best practice initiative (2014-15), he was the highest performing Advisor, exceeding set KPIs. His focus on the priorities of the businesses, not only engaged highest numbers, but delivered highest rate of subsequent implementation support with a > 55% success rate; ie. businesses felt confident to progress with Derek’s support.

Thus, carbon accounting and management have been integral to Ecolibrium’s work for over 20 years.

Summary Cases Showcasing – Resource Efficiency, Circular Economy + Lifecycle Optimisation

In addition to a scientific evidence-based approach, “systems thinking” has contributed so much to sustainable business success over 25 years. Supply chain and lifecycle issues and implications are considered as standard in any project. Opportunities for impact and carbon reduction beyond the site boundary can often be significant.

Quantification of opportunities (in terms of carbon and cost reduction), prioritisation, evidence-based decision making on priorities, objectives + targets and action to deliver.

Johnson & Johnson | Edinburgh, Livingston + Inverness | 1995 to 2011

In 1995, following significant regulatory pressure due to effluent discharge failures (high chromium(VI) and nickel), Derek led a technology evaluation project to rapidly identify a solution. Despite time constraints, the team were able to evaluate a range of solutions and combinations using a resource efficiency approach (ie. not just “end-of-pipe”).

This approach not only delivered legal compliance, but also savings in water, effluent, energy and process chemical costs. The size of the final end-of-pipe reduction / precipitation / flocculation treatment system was also minimised. Following this successful project, Derek / Ecolibrium became J&J’s preferred consultants for 16 years.

Many elements of Circular Economy (CE) are not new. Much of the work undertaken over 25+ years has used CE principles and models; eg. over a range of sectors:

- Gore – Scoping and project development of high value circular / diversion options assessment for Gore-Tex offcuts and other resource streams.

- Oceaneering – support provided, not just for ISO 14001, but also to evaluate options for reuse / re-engineering of subsea umbilicals or reuse of their high value materials at end of their operational lifespan.

- Merson Signs – Undertook EMS and RE work for provider of large scale signage. Rental model based on design for longevity, upgradeability, delivery of long term value and reduced impacts.

- Zot Engineering (PCB manufacturer) – option evaluation for the recovery of high value metals from spent etching solutions.

Thus, systematic and circular approaches have been integral to Ecolibrium’s work for over 20 years!